Under Drain System

USING WORLD RENOWNED STAINLESS STEEL V WIRE SCREEN HEADER LATERAL TECHNOLOGY – Brilliant Renovation of Rapid Gravity Filters to increase efficiency of water filter quantity and water quality in existing WTP filter beds and/or new installations by 60% compared to conventional Header Lateral Filtrations Technologiesand supply safe & quality standard water to communityand Direct saving to the government sector and private sector alike

Our V-wire Under Drain System is designed on collection and distribution theory and eliminates the support gravel layer,stops media mixing problem, provides effective backwash and reduces backwash water consumption.Being the principal manufacturer we have considerable experience and expertise in designing, operating and maintaining under drain systems that perform effectively and reliably in all circumstances.

Indian States already benefitting from the successful installation and functioning of this technology are – Delhi, UP, Uttaranchal, Himachal, Gujarat, Maharashtra, and Karnataka

Working Principle

A Superior Product Through superior Engineering

Rapid sand gravity filter beds are an important element of any drinking water treatment plant and generally the capacity of the entire plant is limited by the filtration capacity of the filter beds. The filter beds mainly carry out the function of fine filtration of the raw water to remove the turbidity of raw water. This is achieved by letting the raw water percolate under gravity through an appropriately sized filter bed of fine sand media. The percolated water is then collected in some collection system laid beneath the bed to give a passage to the filtered water out of the filter bed. This system of collection is popularly known as the Under Drain System.

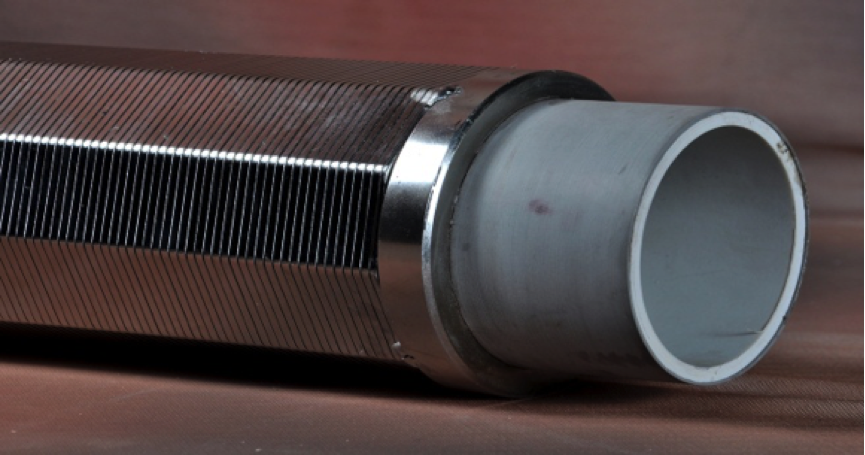

The design of our Underdrain system is based on header lateral distribution theory. This method of collecting and distributing flows is common technology. The Cylindrical Header is installed lengthwise in the center of the bed. One end of the header will be closed and other end will remain open to outlet for the filtered water. The Header will have appropriate connection for fitment of the laterals.

Design Features

DESIGN FLEXIBILITY ALLOWS OPTIMUM PERFORMANCE

- The system is made of Stainless steel grade SS304 which gives very robust construction of system & provides very long life approx. more than 50 years

- Large % open area at fine slots to offer minimum pressure loss

- Uniformly distributed slots across the periphery and length of the screen

- Non-clogging properties of the fine slot

- Separate air distribution for effective washing

- Minimum pressure losses when back wash water and air is passed thru them.

- Sufficient strength and long life non-corrosive.

- Ventury effect at the time of backwashing.

- The system is made from very fine opening (300 micron) eliminates the gravel layer & stop the media losses – This helps maintenance very easy & stop the fillings of Filter media in water reservoir.

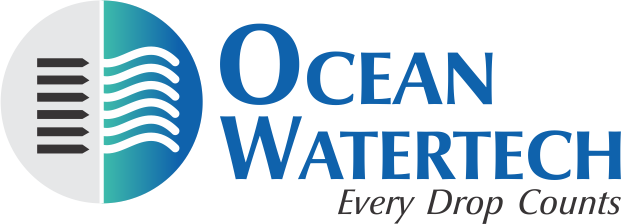

- The pipe base V- Wire Screen Laterals are used which are installed perpendiculars to the header on both sides, spaced equally. The laterals are made from Stainless Steel Grade SS 304 V-Wire Screen technology.

- The internal base pipe holes provide uniform distribution of water back wash by forcing the flow through orifice holes along the length of the lateral.

- The laterals are designed to retain the sand media directly without the need for support gravel. One end of the lateral are sealed and other end with suitable to join with the header .

- Fine slots for direct retention of sand media.

- The lateral of V-wire under drain system is made from a V-wire screen based on PVC pipe fitted with necessary fitting made form PVC & supplied with separate air distribution system.

- The V-wire under drain system has fine slots (holes) enough to directly stop the loss of this fine sand without need for any additional support gravel layers.

Advantages

- Save Space And Money due to no layers of support gravel

- Maintenance Costs Are Reduced as you never have to rebuild your filter

- Trouble free operation

- Filter Bed Capacity of Filtration increases

- Eliminate Bed Upset And Gravel Mixing Problems

- Backwash More Effectively With Air And Water

- Retrofit Or New – Installation Is Easier, Less Costly

- Get Better Quality and Quantity of Water

- Reduction in the civil construction & land cost

- No power required foroperation